Who We Are?

In the year 1996, our journey as a Manufacturer, Exporter and Supplier began in this industry. We have happen to attain a reputed position as today hundreds of clients from Petrochemicals, Refineries & Dye Intermediates, Pesticides and allied industries are associated with us. Our clients find our products reliable because of their easy to use and maintain, sturdy construction, high operational efficiency and allied attributes. By laying great emphasize on the designs of the plants and other products, we provide our customers with effective & long term solutions.

Promise of High Quality

Prakash Industries has always given prior importance to the qualitative aspect of both the products as well as the operations. We have a separate quality control division in Mumbai where a series of inspections are carried out by the experts. By utilizing the modern testing instruments & tools, our experts examine tests the procured raw material as well as the final products. To achieve the set quality standards, we keep improving our systems in a continuous manner. We also make sure that the products like Resin Plants, Grease Plants, Distillation Plants, Agitator, Blenders & Mixers etc. are fabricated as per industry prevailing norms. During the production of these plants & equipment, utmost attention is given on the processes & methodologies to bring forth reliable goods. All the testing & acceptance norms at every stage of production are clearly defined & communicated to the personnel. The parameters on which our product line is tested includes:

- Corrosion resistivity

- Durability

- Ease in installation

- Hear resistivity

- Precision in the structure

What We Offer?

We are dealing in the

manufacturing, exporting and supplying of a broad range of industrial

solutions and plants that are used in industries for varied purposes.

Some of these products are mentioned below:

- Reaction Vessels

- Resin Plants

- Storage Tanks

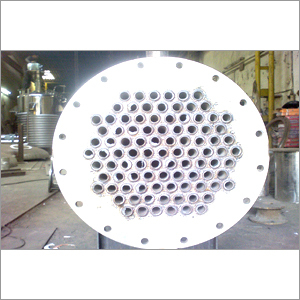

- Heat Exchangers & Condenser

- Distillation Plants

- Grease Plants

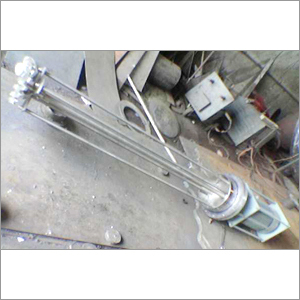

- Stirrer & Agitator

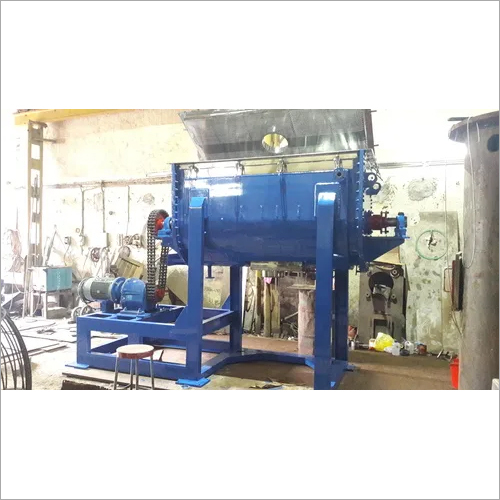

- Blenders & Mixers

- Oil Plant

- High Speed Stirrer

- Emulsion Plant

- Perfume Plant

- Lube Oil Blending Plants

Our Hardworking Team

We have brilliant workforce of diligent professionals, who leave no stone unturned to fabricate goods that are defect free. The team comprises both young and experienced members and the blend of their latest ideas and knowledge, respectively is working as a boon to our company. Our senior experienced engineers are assisted by other professionals in the fabrication process this way both learn from each other and helps in maintaining a good professional environment at workplace.

Our Infrastructure Facility

Our infrastructure is one of the most important resources our company, as it helps is in bringing out goods that are of international standards. All the production related work which involves designing of the layout, manufacturing, assembling, quality testing, packaging and storage is carried out in a judicious and smart way by our highly efficient team. The machines and tools that are used in these procedures are well equipped in our infrastructure and continuously serviced to maintain their operational efficiency. Some of these facilities are:

- Welding Machine Rectifier

- Plate Bending Machine

- Welding Machine Transformer

- Radial Drill Machine

- Plasma Cutting Machine

- Grinders

- Coil Bending Machine

- Gas Cutting

- Hydraulic Test Pump

- Hydraulic Press

Grease Manufacturing Plants

We

have fully fledged Grease manufacturing set up in Mumbai where all type

of Greases are produced with the help of modern equipment. Our produced

Grease is mainly supplied to those areas where it is difficult to

retain Oil as gears or open bearings. Grease manufacturing plant is

installed with grease kettle which is apt to function under different

operational temperature & pressure. The grease kettles are available

in different types such as counter rotating with scrapers and sun &

planetary. Below is the list of equipment that are installed in our

grease processing plant:

- Grease DE-aerator system

- Grease kettle

- Grease milling system

- Pressurized grease cooking vessels

- Small packaging and filling system

Research & Development Unit

Before

designing the structure and engineering the offered plants, we first

understand the ongoing trends of the market and new developments in the

industry. Our team of researchers conduct series of extensive researches

to determine the exact demands of the market and requirements of the

clients. On the basis of collected feedback, our experts decides the

developmental techniques to be followed during the production stages.

These market analysis also helps us in ascertaining the latest

technological advancements of the domain and the type of machinery &

equipment that are best for the production of Distillation Plants, Grease Plants, Stirrer & Agitator, Blenders & Mixers etc.

Client Satisfaction

Right from the inception, we are following client centric approaches that helps us in winning their faith and attaining their complete satisfaction. We don't want that because of us the clients face any kind of inconvenience in their business therefore, we complete all the undertaken projects within the promised time frame. During the execution of the projects, we keep in mind the needs of the patrons and serve them accordingly. For their benefit, we also provide them customization option to meet their specified demands and ensure that products are manufactured under the set standards of the market. Our hard work and untiring efforts enable us to capture a vast clientele in the areas like East Europe, North Europe, Central America, South America, Middle East and South East Asia. Some of our clients include:

- Abhinandan Rasayan Pvt. Ltd.

- Amoli Organics Pvt. Ltd.

- Salvi Chemical Industries Ltd.

- Shiva Petrolubes

- Star Oxo-Chem Pvt. Ltd.

- Sun Pharamaceutical Industries Ltd.

- Yamuna Lubricants

Send Inquiry

Send Inquiry Send SMS

Send SMS